What?

Hathaway Dinwiddie (HDCCO), a general contractor based out of California, utilized OpenSpace on the City of Hope - National Medical Center project in Duarte, California. The project scope included constructing a ground up, 4-story, 88,696 SF medical office building with space for offices, conference rooms, executive offices, kitchen/bathroom amenities, and outdoor space. The National Medical Center building provided the City of Hope Center, one of the nation’s top cancer hospitals, with first class medical office facilities to house and attract top medical professionals.

Why is this important?

In addition to providing City of Hope with first class medical office facilities, the National Medical Center project was HDCCO’s first project with City of Hope. This project gave Hathaway Dinwiddie a great opportunity to make a positive first impression and win more work with them in the future.

HDCCO was able to use a technology-first mentality to help deliver a successful project. The team utilized OpenSpace in several ways not only to help their team, but to give the owner and design team remote jobsite visibility throughout the project. Some ways that the HDCCO team utilized OpenSpace to deliver a successful project include:

-

Validating change orders by using OpenSpace captures to see when certain trades were installed or where damage may have occurred. The captures provided the team with all of the photo documentation they needed to quickly work through change orders throughout the project.

-

HDCCO installed a Variant Refrigerant Flow (VRF) HVAC system for this project and OpenSpace captures helped the team track installation progress and schedule inspections.

-

Some remedial work for embed installation had to be performed and HDCCO was able to use OpenSpace to validate the location of post tensioning cables and show the structural engineer where embeds could be installed. This saved the project team close to $100k in change orders.

-

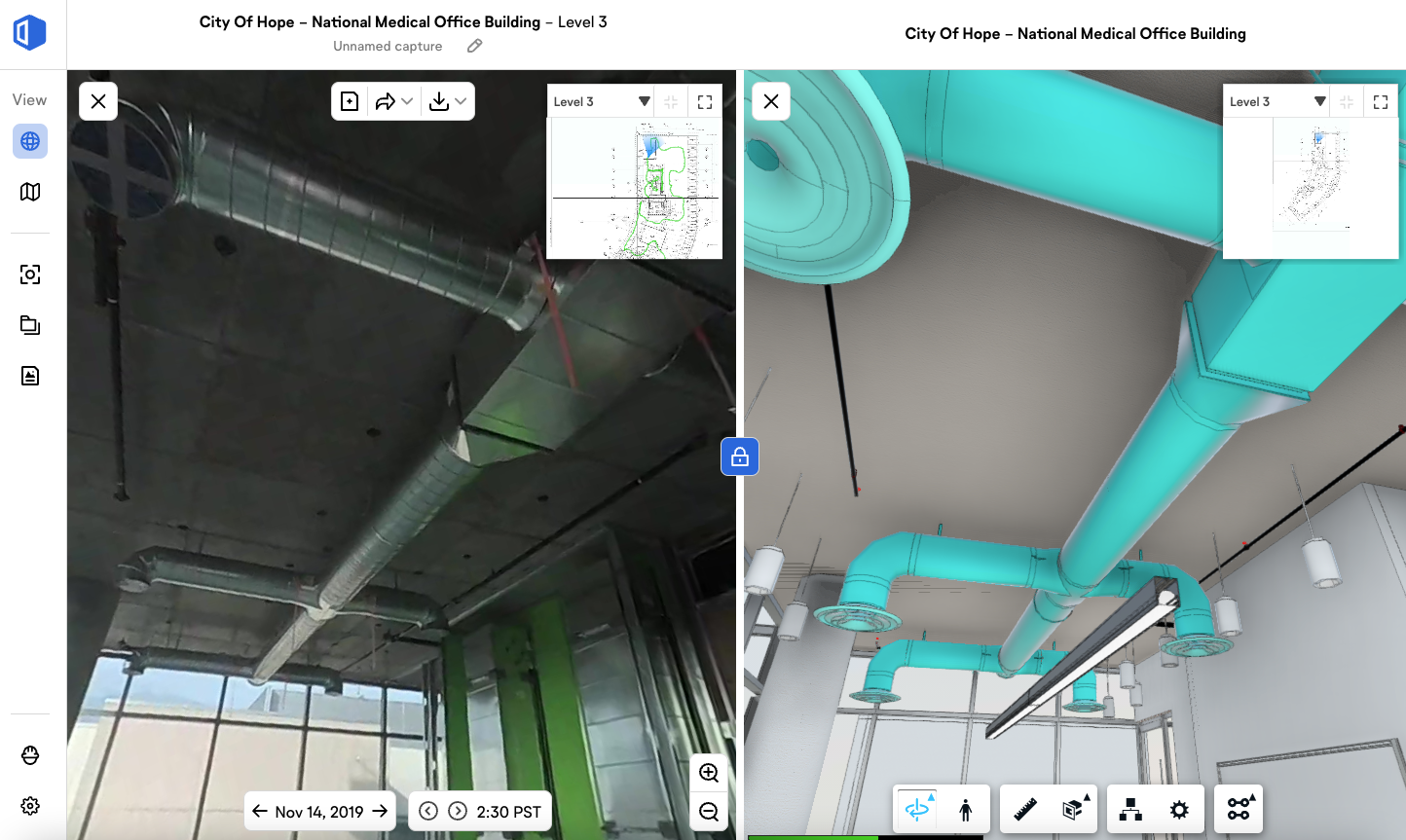

HDCCO team was able to quickly go back through captures and verify where pipe sleeves, deck inserts, and floor boxes were installed. The team was able to validate that everything was installed per plan by utilizing the BIM Viewer and pulling up their capture next to the BIM model.

-

OpenSpace access gave the Owner and Design team remote jobsite visibility during COVID to help with coordinating schedules and verify work in place.

Key Benefits of Using OpenSpace

Remote jobsite visibility for remote owner and design teams

Remote jobsite visibility for remote owner and design teams

Complete progress documentation to help with change order validation

Complete progress documentation to help with change order validation

Virtual progress tracking for scheduling and cost validation

Virtual progress tracking for scheduling and cost validation

Using the Split View feature to compare pre and post slab pours to verify installations

Using the Split View feature to compare pre and post slab pours to verify installations

Adding additional photo documentation and issue tracking through the use of Field Notes

Adding additional photo documentation and issue tracking through the use of Field Notes